High-performance polymers are an essential tool for treating water and sludge, whether in industrial processes or municipal wastewater networks. But there’s a catch. Making these polymers requires fossil-based feedstocks, which are neither renewable nor climate friendly. At the same time, regulations related to water treatment continue to tighten, which means demand for high performance sustainable water-treatment chemistries is increasing.

“As an industry leader and frontrunner in sustainable chemistries, Kemira has a responsibility to help water-intensive industries address this challenge,” says Peter Ersman, Senior Vice President, Product Lines, Industry & Water, Kemira. “Sustainable chemistry and circular solutions have been part of our DNA for decades. For example, in one of our core product lines for water treatment, inorganic coagulants, we already today have a majority of the raw materials coming from recycled sources or industrial by-products. ”

Sustainable chemistry and circular solutions have been part of our DNA for decades.

The latest step on the road towards our sustainable portfolio transformation is the introduction of innovative and renewable alternatives for fossil-based organic polymers, which is Kemira’s second-biggest product offering for demanding water-treatment applications.

Revolutionizing the industry with renewable water-soluble polymers

In 2021, Kemira’s long-term commitment to developing renewable chemistries took a big step forward with the start of full-scale production of a newly developed water-soluble polymer offering – our Superfloc® BioMB portfolio. The biomass-balanced (BioMB) product is revolutionary because it is made using renewable feedstock instead of fossil raw materials. The first batches were delivered to Helsinki Regional Environmental Services (HSY).

Wido Waelput, Senior Vice President of Kemira’s Industry & Water Segment in EMEA and Asia-Pacific adds: “Chemical performance is, naturally, top of our customers’ priority list, but more and more customers now need ways to increase the sustainability of their operations, and polymers based on renewable feedstocks offer a simple way to do this without impacting process performance.”

One of the biggest advantages of biomass-balanced polymers is that they are a risk-free drop-in solution for water-treatment applications. Customers can take immediate action to reduce the carbon footprint of their operations without needing to requalify the chemistries, change their processes, or worry about process performance.

Customers need ways to reduce the carbon footprint of their operations, and polymers based on renewable feedstocks offer a simple way to do this without impacting process performance.

What are biomass-balanced polymers, and how are they made?

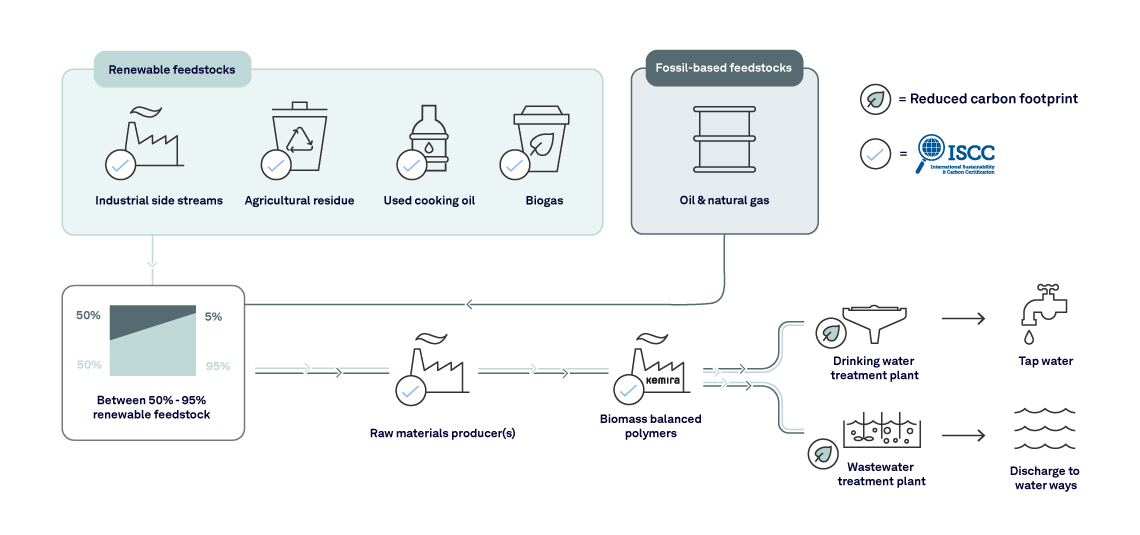

When a polymer is biomass-balanced, it means that the majority of the fossil-based raw materials used to manufacture it are replaced by renewable mass-balanced feedstocks. These feedstocks – which can come from sources such as industrial side streams, agricultural residues, used cooking oil, and biogas – contribute to carbon reduction by sequestering carbon from the atmosphere.