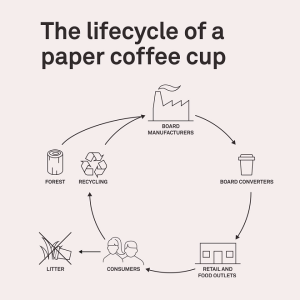

From tree to board

Just like all the best stories, this one begins in the forest, where trees are felled ready for processing into pulp and then cup board material at a mill. At this stage the board manufacturer is looking to achieve process conditions that will help them maximize their production efficiency; in other words, they want to ensure speed and runnability on the board machines – which can produce hundreds of tons of product a day – and squeeze as much board out of a machine as possible. The board that comes out at the end of the process has to be safe to use, have the necessary properties for converting, and must also be easy to recycle.

Chemistry’s role at this stage of the lifecycle is to make sure that the board has the desired strength, stiffness, safety, hygiene, and water-repellant properties – as well as printability – for paper cup production. To take just one example, chemistry is used to make each fiber stronger, meaning we need fewer fibers to make each cup.

Crafting the cup

Modern cup converting machines are fast, producing somewhere in the region of 330 perfectly formed cups a minute. But high-speed processes bring with them high demands on the material that’s fed into them. This is where formability – the ability of a sheet material to deform without failure or fracture – is critical. The board has to offer exactly the right kind of formability to enable it to whizz through the high-speed machines and be carefully but quickly formed into cups. Once again, chemistry is at work behind the scenes, enabling the production of low-weight boards that still offer the elasticity and stiffness that converters require.

Chemistry ensures paper cups are hygienic and prevents them from falling apart when filled with liquid

Ready for filling

After leaving the converting line, the cups are ready to start their journey into the hands of consumers via food-service providers, which could be anyone from your local corner coffee shop to the nearest branch of a global fast food chain. Of course, the cup that holds your morning cappuccino to go has to be safe and hygienic; it also needs to be pleasant to the touch and prevent your fingers from getting burned.

For food-service brands, paper cups are far more than just a convenient way to serve take-away beverages – they’re also an ideal marketing platform. New and innovative printing and smart-branding techniques are transforming the paper cup into a powerful brand ambassador.

From cup back to board again

Returning to the start of the coffee cup lifecycle, chemistry enables the fibers from the cup to be recycled many times over to produce new fiber-based products for non-food uses, which reduce the use of virgin raw material. De-inking chemicals are used to remove inks from the recyclable board ready for reprocessing. Once the fibers have been processed and any surplus plastics screened out, the resulting material can be used to manufacture products like testliner, white lined chipboard, and core board.

Chemistry makes it possible to use recycled fibers from paper cups to produce board materials for non-food uses.

The choice is ours

After you drink the coffee, the fate of the cup is in your hands. Making 100% recyclable cups is no use if we simply toss them on the floor instead of into the nearest recycling or waste bin. We can only make the zero-waste coffee cup a reality when we take responsibility for our own actions and push decision-makers for legislation and recycling systems that close the loop.