Kemira has embraced the biomass balance approach as a way to reduce the use of fossil carbon across the papermaking value chain without jeopardizing operational efficiency. Biomass-balanced wet strength additives, launched at the beginning of 2024, offer a more sustainable alternative to conventional, fossil-based strength resins. These additives are crucial in producing moisture-resistant paper, board, and tissue grades and molded fiber products.

“Our customers are seeking more sustainable solutions for different applications within the papermaking process, but don’t want to and cannot compromise their processes’ runnability or production efficiency,” acknowledges Mira Koivula, Vice President, Product Line Management in Packaging & Hygiene Solutions at Kemira.

Biomass-balanced products tick both boxes. They are genuine drop-in solutions with immediate sustainability benefits. The biomass-balanced wet strength resins maintain the same high quality and performance as standard products, while effectively reducing the use of fossil raw materials in the value chain.

“The market response to our biomass-balanced wet strength additives has been particularly encouraging,” Koivula notes. “Customers have quickly embraced these solutions, which clearly demonstrates that they recognize the value and that we’re meeting a real need: offering solutions that deliver both sustainability benefits and the proven performance our customers rely on.”

Kemira’s biomass-balanced products contain at minimum 50% renewable carbon through mass balance attribution. In Kemira FennoStrength™ wet strength additives, the renewable carbon content can be increased to 75% or even close to 100%, depending on the product.

Kemira is introducing a diverse range of other biomass-balanced alternatives to the market, e.g. for surface sizing and barrier applications, in addition to the wet strength additives and biomass balanced polymers for retention and drainage and water treatment applications, which were launched already in 2021. “Adopting this principle broadly supports our long-term goal to build a leading portfolio of renewable solutions to help our customers in their sustainability transformation,” Mira states.

Adopting this principle broadly supports our long-term goal to build a leading portfolio of renewable solutions to help our customers in their sustainability transformation

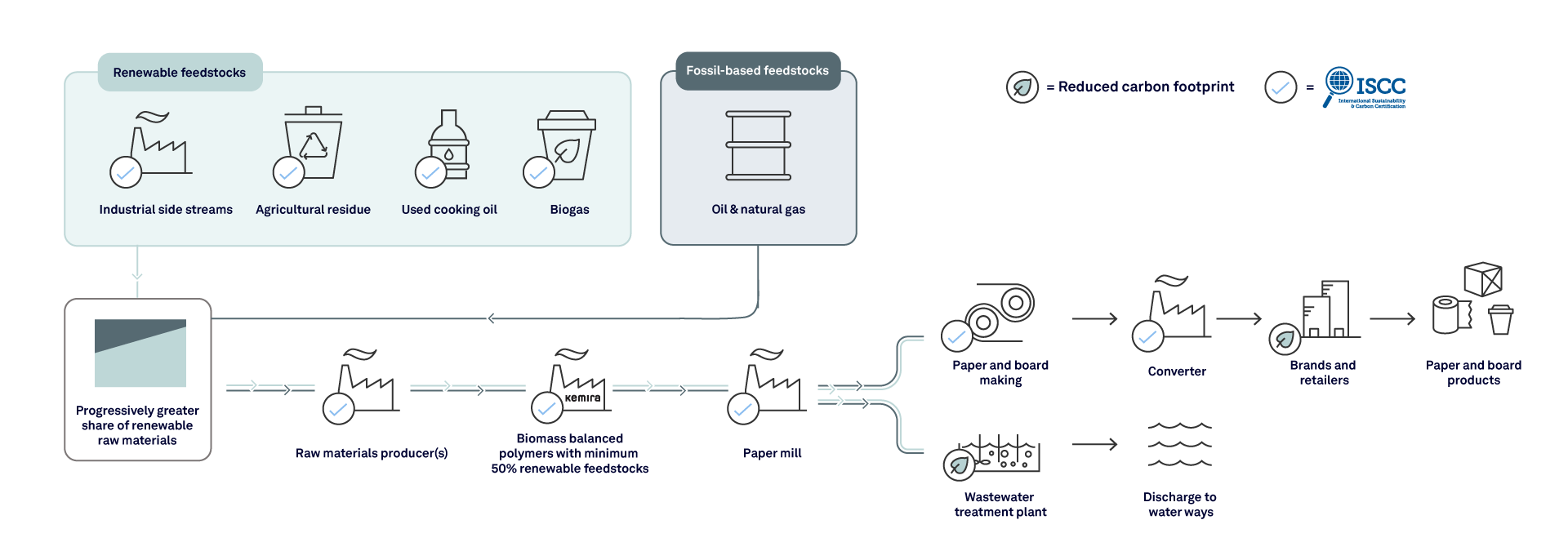

Mass balance approach explained

“The biomass balance concept might seem complex, but it’s similar to the principle behind green electricity,” assures Mira. Simply put, it means that a major share of the traditional fossil-based raw materials is replaced by renewable mass-balanced feedstocks at the very beginning of the production value chain. These certified renewable feedstocks – such as biogas or agricultural waste – contain renewable carbon and thus increase the overall renewable content in the value chain and contribute to fossil carbon reduction.

An independent third-party certification guarantees full traceability; ensuring that the correct amount of renewable raw materials is used and that these raw materials come from verified sustainable sources. Kemira’s biomass balanced products and their manufacturing sites are certified according to ISCC (International Sustainability and Carbon Certification) PLUS standards.

“This is a value chain effort focused on driving environmental impact,” Mira emphasizes. “By replacing fossil resources with renewable and circular materials within the existing production processes, we can collectively take an effective climate action and contribute to the shift away from fossil carbon.”