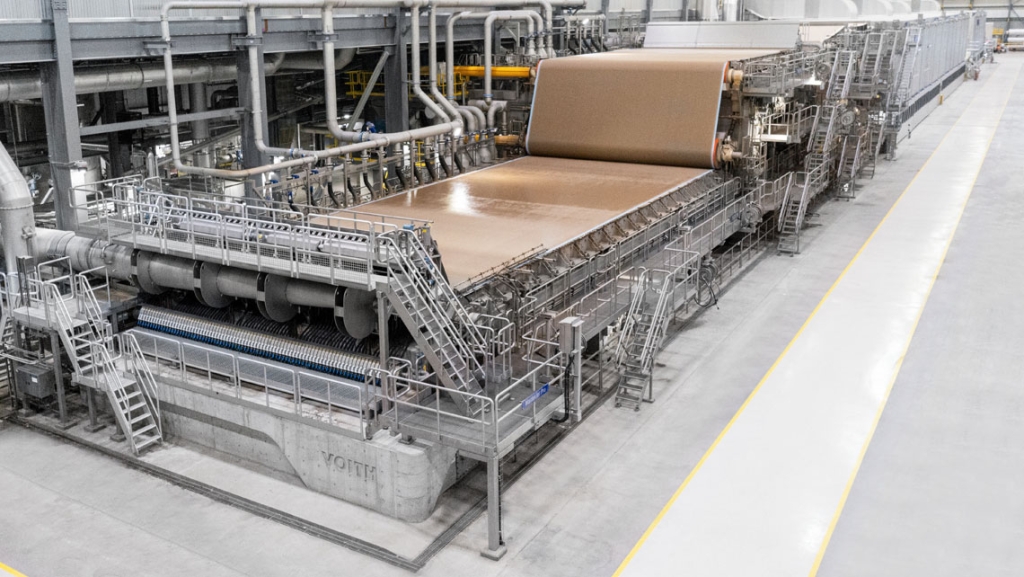

In March 2021, Green Bay Packaging’s new paper machine began production in Wisconsin, North America, producing medium and liner board from recycled fibers (OCC pulp). One of the key partners behind the successful machine start-up was Kemira and its team of experts. Kemira is responsible for all chemistry applications on the paper machine and recycled fiber plant of the new Green Bay Packaging Wisconsin mill. Now, after start-up, Kemira continues to operate and optimize the chemical systems at the world-class facility.

“Having a committed partner like Kemira as a chemistry supplier was critical to our success,” states Todd Schumacker, Production Manager at Green Bay Packaging.

“We were able to have one point-of-contact for the chemical applications, which was extremely important as we managed a very challenging start-up process with an entirely new water system and stock system. Kemira took responsibility for the chemical applications and systems allowing us to focus on the entire mill setup. This brought the greatest value to us.”

In this article, Kemira experts David Flaker, District Manager, and Sales Representatives Trevor Snyder and Benjamin Benaszeski, who all were among the hard-working team at the Green Bay start-up, share what it takes to make a paper machine start-up a success.

Engineered with chemical expertise

The first thing is to involve the chemical supplier early in the planning stages of the project. At Green Bay Packaging, Kemira’s experts were engaged from the start: from specifying the start-up chemistries and equipment to taking on the responsibility of the chemical system planning in close collaboration with mill engineering.

“A paper machine start-up is always a complex project with many stakeholders. The benefit of having the chemistry experts’ input in the project earlier rather than later, is that we can bring in a different and unique perspective to the mill design and insight into all the phases of the papermaking process. In addition, we have a lot of engineering capabilities from the paper machine chemical system perspective,” states David.

Todd Schumacker appreciates the excellent relationship that Kemira’s team developed with Green Bay Packaging’s own team and with their chosen engineering partner and machine supplier.

“Kemira’s team was an integral part of this project. For example, we had several programming challenges on start-up that prevented the chemical systems from feeding properly. Kemira took responsibility to get these issues corrected and spent long hours working directly with the control system programmers. They didn’t wait for someone to do this for them but made it happen – a sign of a strong partner,” he praises.

The early involvement also allows the chemistry experts to advise for example on the optimal equipment placement in the mill layout or to spot issues that could impact logistics and chemical unloading later.

“These types of issues can unnecessarily complicate the operations after start-up at the site and even cause extra costs for the customer, not to mention that they are difficult to fix afterwards,” Benjamin points out.

One simple example are the storage tanks: optimizing the tank sizes to suit the needs of the process in the planning stage ensures smooth and cost-efficient papermaking operations at the mill.

Covering all the phases of paper making

Kemira’s application expertise at Green Bay Packaging’s new machine covers the end-to-end papermaking process from retention and drainage technologies, defoamers, deposit control, and microbiological control to sizing and colorants, and more. A holistic approach to chemistry management is a key factor to a successful start-up, and Kemira experts’ second recommendation.

Picture provided by Voith

Applying chemicals in fast, modern paper machines requires special attention: both the dosing points and the mixing systems need to be carefully designed to match the unique reactions of each chemical additive. When planning for the start-up, Kemira’s experts utilize advanced tools e.g. for modelling liquid flows.

“This way, we are able to accurately plan the right injection points for delivering the diluted products into the process with optimal distribution. This improves chemical efficiency and can even impact things like water consumption.”

Quality from the first reel of paper

At Green Bay Packaging, no production was lost on paper machine start-up due to issues with the chemical applications.

“This is our main goal: to ensure performance and quality from the first reel of paper and support the mill in achieving full production capacity as quickly as possible,” points out David.

This is our main goal for paper machine start-ups: to ensure performance and quality from the first reel of paper.

“We needed Kemira to take responsibility for the chemical applications and chemical systems to make the project a success. From design to start-up, they not only delivered but exceeded all expectations,” states Green Bay Packaging’s Todd Schumacker.

A greenfield machine project always starts from a clean slate. This is where the end-to-end chemistry capability and application expertise come into play. With it, Kemira experts know how to plan and pick exactly the right kind of products for different furnishes, operating conditions, and grades and meet both the quality parameters and any specific customer requirements for the papermaking chemicals.

“In addition, we always come prepared for the worst-case scenario. At Green Bay, we chose alternatives for key chemistries and ensured approvals for multiple products beforehand. This way, we would have had an immediate solution to try out and take into use quickly, if something should have gone wrong,” Trevor states.

Toward continuous process improvements

After a successful paper machine start-up, Kemira experts turn their focus toward making continuous process improvements to increase board machine efficiency.

“Based on the great collaboration during the start-up, we are looking forward to ideas from Kemira to continuously improve the machine performance and quality. Kemira has been a reliable partner for us, and we appreciate the team’s commitment to our success.”

Matthew A. Szymanski, Vice President of Mill Operations at Green Bay Packaging

“At start-up, everything is new so there’s always room to optimize. We concentrate on enhancing the performance of the chemical programs and ensuring stable, high product quality for our customer with online measuring and monitoring solutions, and also by doing a lot of laboratory work and analysis. Going forward, this typically also translates into improved cost-efficiency,” state Trevor and Benjamin.

Contact our experts to learn more about the Total chemistry management for paper machine start-ups!