Most of us have come across molded fiber packaging as items such as egg trays or cup holders from fast food restaurants and other protective packaging in consumer goods. Today, molded pulp-based packaging is increasingly used in higher-value applications, such as packaging for food and beverage, electronics, and cosmetics.

The interest in molded fiber packaging is growing because it offers a combination of benefits. The key driver is sustainability: molded fiber is renewable, recyclable, and a more environmentally friendly alternative to plastic and other non-biodegradable materials. As such, it helps meet the demand coming from both the consumers and regulation.

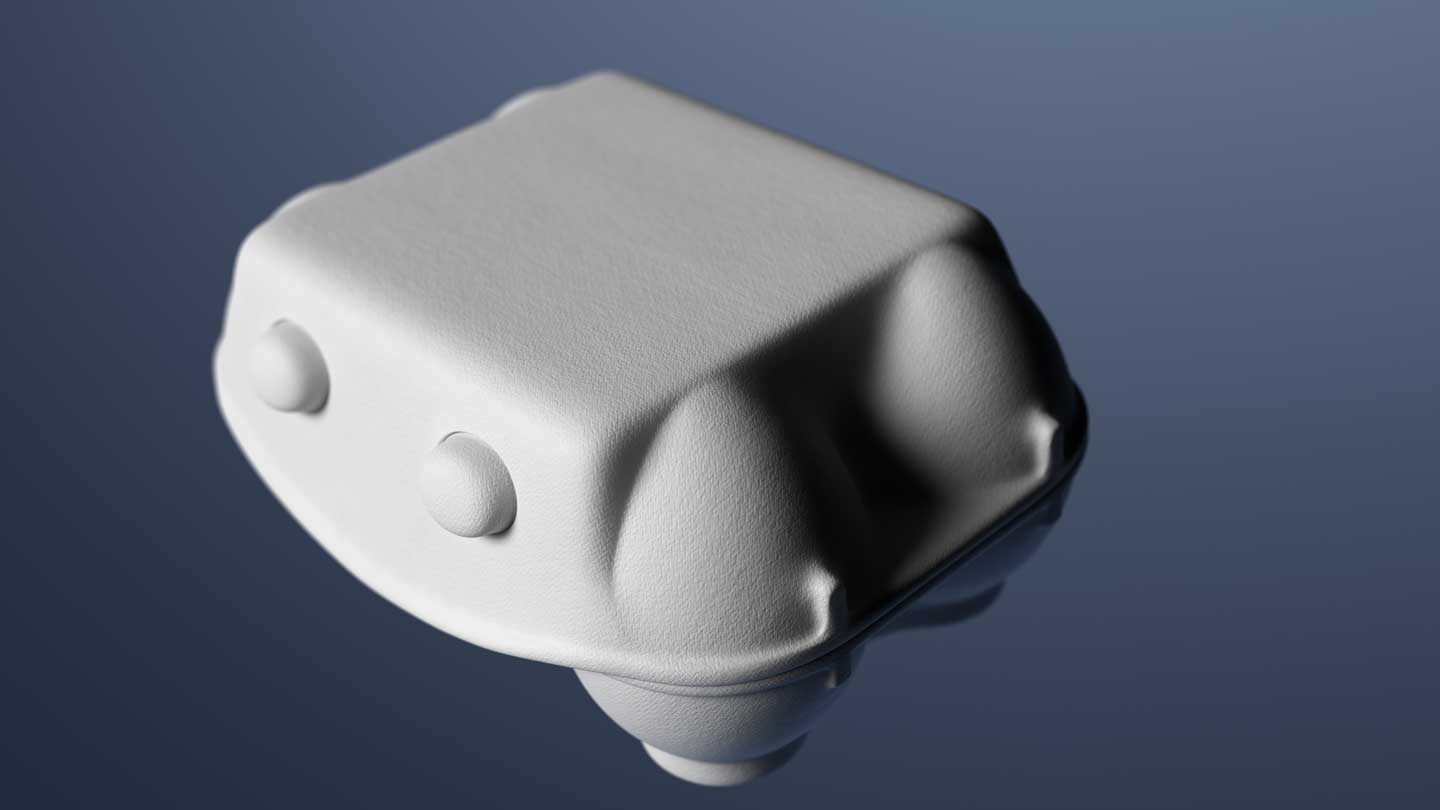

“In addition, molded fiber provides brand owners an opportunity for highly customized packaging in terms of design, shapes, and sizes. It is a versatile packaging material that can fit many specific end-uses. Currently, the trend to replace plastic is particularly boosting high-end molded fiber packaging made of virgin fiber, intended for demanding end-uses and luxury packages,” says Alexander Beam, Senior Global Business Development Manager for Molded Fiber at Kemira.

Chemistry enables functional and safe molded packaging

When replacing traditional single-use plastic solutions in packaging with new, more sustainable alternatives, the challenge is always to do it without compromising on functionality, safety or cost-efficiency. This is where chemistry comes into the picture, enabling the use of cellulose-based raw materials in different end-use applications.

“Chemistry is the invisible enabler for any type of fiber-based packaging. In molded fiber, chemistry is one of the three main variables in the production process along with fiber choice and machine parameters. Chemistry expertise is key in creating the desired properties for the intended packaging end-use and in ensuring efficient production processes, both in terms of cost and raw material efficiency,” explains Alexander.