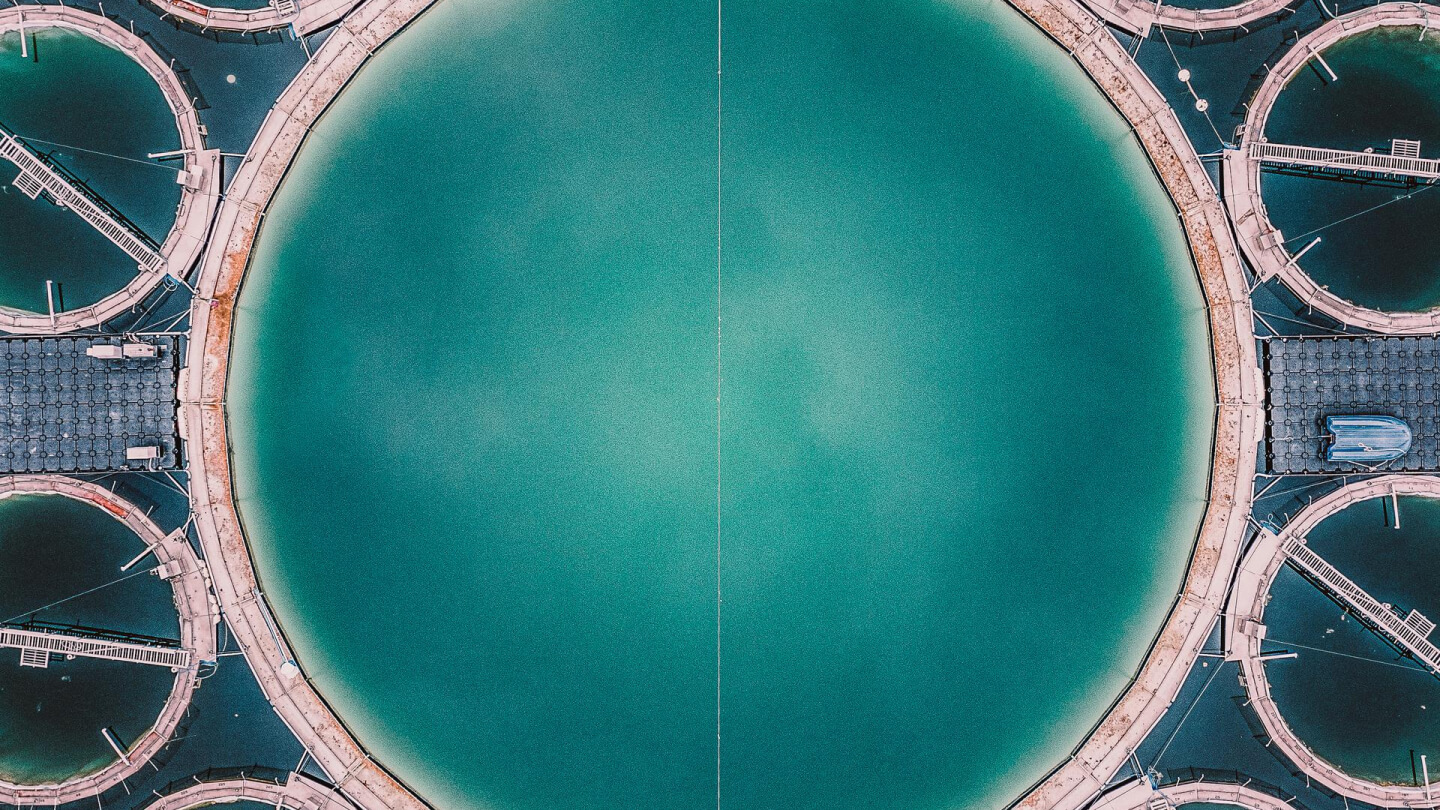

From linear to circular

The circular economy goes far beyond recycling. It requires fundamental changes to the way materials are sourced and how products are designed, produced, sold, used, and disposed of. Kemira is transforming chemistry value chains by creating renewable and recycled solutions that improve resource efficiency and circularity. Today we have five principles that guide our approach to the circular economy.

Kemira’s circular economy principles